STAGE 1

Iron ore (nmdC)

STAGE 2

sponge iron (in house)

STAGE 3

melting (direct HOT CHARGING)

STAGE 4

steel billets (in house)

STAGE 5

chemical testing lab

STAGE 6

cnc rib cutting

STAGE 7

tmt bar rolling

STAGE 8

thermex quenching process

STAGE 9

physical testing lab

STAGE 10

cutting & bending stockyard

STAGE 11

tagging

STAGE 12

dispatch

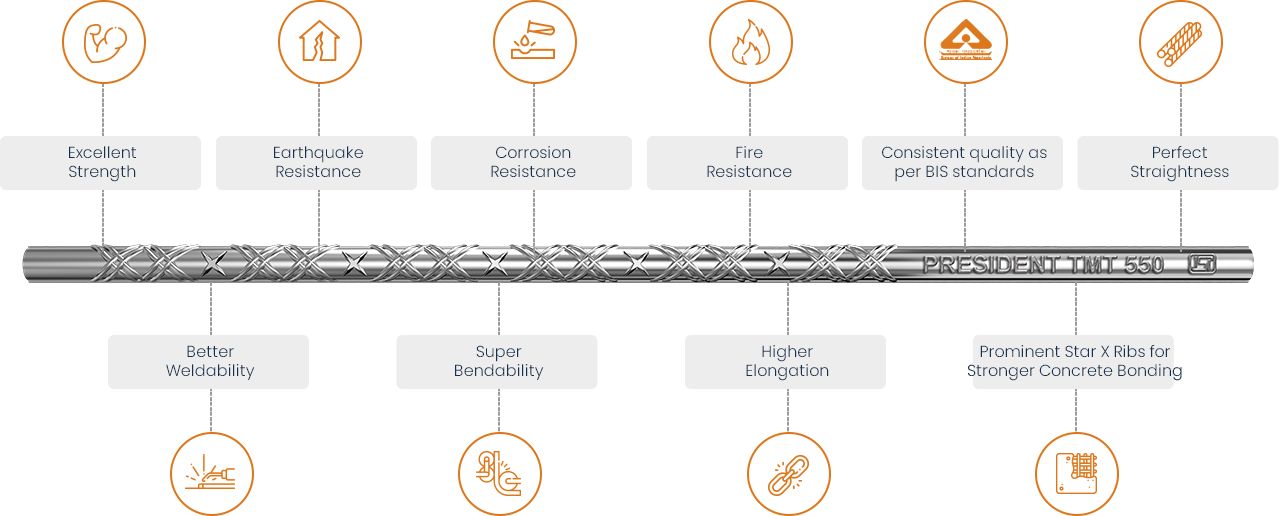

Product Advantages

TMT Bars Steal the Show:

6-7% Steel-Saving

A Solid Bonding with

Concrete

Low-Carbon TMT: Small step

towards a greener planet

President tmt bars V/S other brands

|

Hign elongation provides high seismic resistance. | Comparatively less elongation doesn’t provide as much seismic resistance. |

|

Flawless manufacturing process gives the bars a unique micro structure for better corrosion resistance. | Don’t provide adequate corrosion resistance. |

|

Superior ‘STAR X’ Rib design with greater depth and closer rib spacing ensures a better bond with concrete. | Other bars do not come with the unique rib pattern. |

|

Uniform length of 12 metres make the bars ready for construction, avoid wastage and save man-hours. | Inconsistent bar size adds to construction cost and results in wastage. |

|

Superior bendability makes the bars easier to work with, thanks to its unique combination of a tough outer edge and softer inner core structure. | Low bendability makes the bars brittle, hard to work with and easily prone to cracks. |

|

Superior weldability ensures optimal strength of welded joints without requiring any additional pre or post welding treatment. | Requires pre and post welding treatment which adds to construction costs. |

President tmt FE 550 – 10 OUT OF 10